The first recognisable form of golf was played in Scotland in the early 1400s - since then, the golf ball has had nearly 600 years to develop and progress in keeping with modern golf trends.

Over this period of time, the development of the golf ball has continuously affected the rules of golf in its entirety, including the rules surrounding the golf club and the golf course.

So, where did the golf ball start, and how did it come to be what we know it as today?

This blog takes you through each key development in the history of golf balls timeline, from its inception in the early 1400s to today’s modern golf ball design.

The history of golf balls:

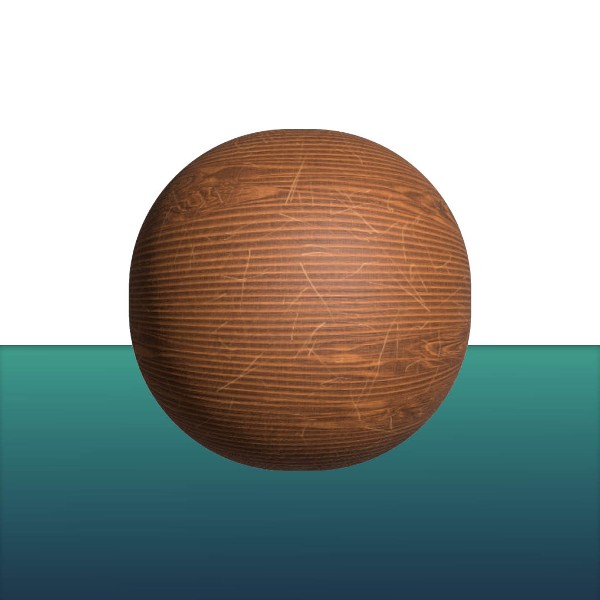

Wooden golf balls - 1400s

Unfortunately, there is no historical evidence as to how golf came to be, but it is generally agreed that 'gowf', 'goff' and eventually, ‘golf’, originates from the medieval Eastern Coast of Scotland.

During this period, wooden golf balls were made by carpenters using a combination of Beech, Boxroot and hand tools.

Wooden golf balls were only used up until the early 17th century, as they were very inefficient and difficult to play with. This is because it was hard for the carpenter to get the wooden balls perfectly round.

Hairy golf balls - 1486 - 1618

During this time, hairy golf balls were also used by golfers. The origin behind this funny name is because these golf balls were hand-sewn and filled with cow's hair or straw.

The Scottish received these hairy golf balls as they were imported from the Netherlands between 1486 and 1618. They eventually ran their course, as players realised that the hairy nature of the golf balls didn't bode too well with the wet Scottish weather.

There is quite a bit of overlap between the usage of the hairy golf ball and the featherie golf ball (which we'll learn about next!). This is because the hairy golf ball was cheap, so it became known as the 'common' ball, whereas the featherie was expensive to make, but more effective in play.

Featherie golf balls - 1689

The featherie ball became the standard golf ball for around three centuries, making the wooden and hairy golf balls obsolete in its wake. It was a leather ball, stuffed with boiled goose or chicken feathers, which was then stitched shut and painted.

It was seen as a development of the hairy golf ball, as it could be stuffed with more material than the hairy golf ball, making it harder, and able to fly farther.

The arduous process of manufacturing these featherie golf balls became its downfall, making them incredibly expensive and inaccessible to 'common' golf players.

Another issue with the featherie was the golf ball material itself. If it became wet upon impact, it would easily split and damage.

To put the ineffectiveness of the featherie golf ball into perspective...

- It would take a whole bucket of goose feathers to make one featherie golf ball.

- A golf ball maker would only have the time to produce four of these in a day.

- A player would only be able to get 2 rounds out of one featherie golf ball.

- If it got wet (which isn't hard in the Scottlish links) the manufacturing process would have to start all over again!

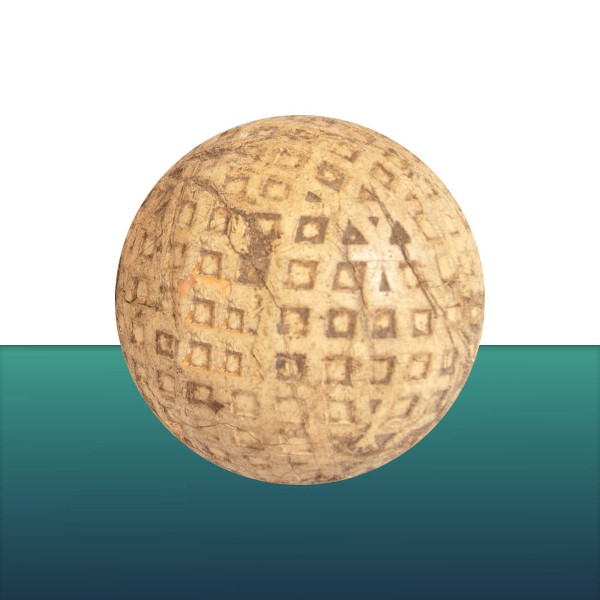

Guttie golf balls - 1848

The guttie golf ball was the first ever moulded golf ball. The guttie golf ball, also called the Gutta-Percha ball, was made by Robert Adams Paterson in the mid-1800s.

Whilst its reign didn't last anywhere near as long as the featherie golf ball, it still made the biggest impact to golf ball manufacturing in terms of its affordability, playability and durability.

To make the guttie golf ball, Paterson used the sap from the Malaysian Sapodilla tree, heated it up, and formed a ball using a round mould. Due to this manufacturing process, it was the first golf ball that was able to be mass-produced.

This meant that the guttie golf ball was less expensive to make, more accessible for players, easily reformed and had better aerodynamic properties due to its standardised, re-mouldable shape.

Another reason why the guttie ball was so iconic was because it fixed the previous problem of golf balls not being round enough. The guttie golf ball could be easily reheated and remoulded if they lost their shape.

Why do dimpled balls fly farther?

The guttie golf balls contributed to the awareness of aerodynamics in the manufacturing of golf balls. As guttie golf balls were used more frequently, people began to notice that those with nicks and scuffs had a more direct flight path than those without.

The nicks in the golf ball helped to stabilise the ball during its flight. From this, golf ball manufacturers began to carve and chisel different textures into the surface of guttie golf balls to find the most conductive pattern for a direct shot.

These were then called 'Hand Hammered Gutta Balls' - and they had a huge influence on the aerodynamic dimples used on golf balls today.

Haskell golf balls - 1898

What we now know as the basis of the modern golf ball, was actually made as a mistake!

In the late 1980s, Coburn Haskell went to B.F Goodrich's rubber goods factory and got a bit bored - so he started putting together a bunch of rubber bands.

He bounced it, to discover that it contained huge amounts of energy. At this point, the guttie ball was merely a figment of the past.

The haskell golf ball took inspiration from the guttie ball and used a solid round core wound with a layer of rubber, surrounded by a shell of Balata sap.

Progression and modification in the 1960s

The Balata sap was a soft, viscous fluid that was then hardened to create the inner core of a golf ball, but it was still susceptible to dents and knocks.

In the 1960s, a new form of resin called Surlyn was introduced, providing a stronger, more durable cover for golf balls. This was especially effective when used in cohesion with urethane blends which are still used today.

Developments in the 1900s

These balls had the same bramble-like spherical bump pattern as the guttie balls, but it was then discovered in the 1900s that inverted dimples gave the golf ball better control and flight pattern.

This introduced the modern appearance of the golf ball that we are commonly accustomed to nowadays! The newly developed aerodynamic dimples allowed for golfers to maintain a controlled flight, with golf pros being able to put a backspin on the ball.

What is the standard for a modern golf ball?

Haskel's rubber golf ball has provided the standard model of a golf ball since its creation. This is mainly due to Haskel's unique layering techniques which gave freedom for golf manufacturers to develop and create golf balls with varied properties and features that can aid players with specific elements of the game.

Whilst there is some freedom within this golf ball manufacturing method, some basic elements must remain, as the Rules of Golf state:

- The diameter of a 'conforming' golf ball cannot be smaller than 1.680 inches.

- The weight cannot exceed 1.620 ounces.

- The golf ball must also have spherical symmetry.

Current and future trends of golf balls

On average, the two-piece Surlyn golf ball is the most popular among amateur golfers, as they are more durable than the Balata.

Many pros prefer the soft and lively Balata balls as they can achieve their preferred distance and spin with better control.

Whilst new technologies continue to shape the formation and development of the golf ball we know and love, it's important to know and be aware of the fact that it has a rich history.

In this case, 'a golf ball is a golf ball' simply doesn't apply, and many leading-edge technologies will continue to pave the way forward for future golf players and their golf balls.

Buy Personalised Golf Balls Our Blogs

If you have any other questions about the golf balls we provide or how to make your own personalised golf balls, do not hesitate to get in touch with our team and we will be happy to assist you.

Read more – Why Do Golf Balls Have Dimples?